Thermally conductive insulator – EU-INSK52-2

EU-INSK52-2 consists of Dupont Kapton polyimide film, precoated on both sides with thermally conductive Phase Change Material. The material is dry to the touch and flexible at room temperature. When placed between two rigid, rough, uneven surfaces and heat (>52°C) and pressure (4.5psi) are applied the following occurs:

1) When the heat exceeds 52°C (either from electronic component heat-up or because of externally applied heat) the PCM (Phase Change Material) becomes a soft, thixotropic consistency;

2) The physical pressure on the component causes the PCM to flow into the micropores of the component and heat sink, expulsing air from these pores;

3) The Kapton provides an excellent electrical insulation.

| Features&Benefits |

|---|

|

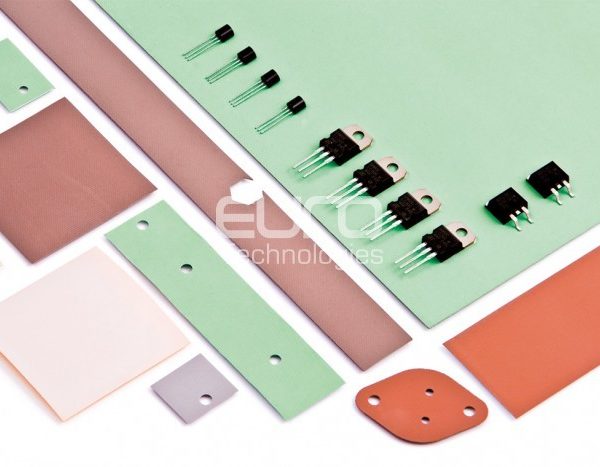

| Configurations |

|

| Typical application |

|

Product properties

| Properties | EU-INSK52-2 | Unit | Test Method |

|---|---|---|---|

| Colour | Amber | – | Visual |

| Substrate Material | MT Polyimide | – | – |

| Substrate Thickness | 0,051 | mm | – |

| Total Thickness | 0,076 | mm | – |

| Tensile strength | 18 | kpsi | ASTM D412 |

| Operating Temperature Range | -60 up to 150 | °C | – |

| Dielectric with Stand Voltage | 6000 | VAC | ASTM D149 |

| Dielectric Breakdown Voltage | 7800 | Volts AC | ASTM D149 |

| Volume resistivity | 4×1014 | Ohm-cm | ASTM D257 |

| Dielectric constant @ 1 MHz | 1.8 | ASTM D257 |

Total thermal resistance

| Pressure, psi | Units | 10 | 20 | 50 | 100 | 200 | 400 |

|---|---|---|---|---|---|---|---|

| ASTM D5470 mod. | °C-in² / watt | 0.23 | 0.23 | 0.22 | 0.22 | 0.22 | 0.22 |

| ASTM D5470 mod. | °C-cm² / watt | 1,48 | 1,48 | 1,42 | 1,42 | 1,42 | 1,42 |

CUSTOMIZATIONS

CERTIFICATIONS

GENERAL CATALOGUE

Euro Technologies offers a wide selection of products. Inside the general catalogue are described, each range, including its features and benefits, specifications, the available variants and possible applications.