CoolShield Solution

CoolShield Solution

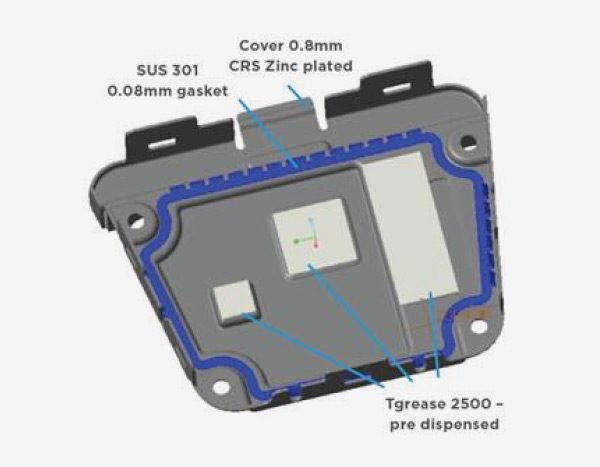

CoolShield solution is to integrate thermal products to shielding cover so that it can provide both EMI shielding and heat transmission for ICs on electronics devices. Here, shielding cover can be a piece of stamped metal, a deep draw cover or even a die casting part while thermal product can vary according to application requirement including thermal pad, thermal grease, thermal Gel, phase change material, etc. With unique automation technology developed by Laird Performance, we can ensure a cost-effective assembly.

Laird Automation

Tim-Pick uses robotic motion control with an innovative “pick head”. This head enables the cutting, removal from an uncut TIM sheet and placement of a “cut to dimension” pad onto an electronic component in one process step. TIM Pick scales well to a fully integrated assembly process including automated feed, shuttle and in-line inspection systems. In addition to reducing costs and improving speeds, TIM Pick can be used to apply materials that are traditionally difficult to hand apply, thereby reducing scrap and enabling the use of materials with improved properties.

Dispensing is an automated process for putty or Gel type thermal interface material. It uses air pressure or pumps to deliver TIM to required interface through a nozzle. Laird dispensable gap fillers are used to bridge the interface between hot components and a chassis or heat sink assembly when elimination of mechanical stress or bulk automated dispensing are critical design considerations. These materials can be dispensed to fill large and uneven gaps in assemblies and due to their super compliant nature; little to no pressure is transferred between interfaces.

BLS and TIM Interactions

A surprising finding of Laird is that putting a thermal material into a shield might cause reduction of shielding effectiveness. Measuring and EM simulation studies were run to investigate the root causes and to provide solutions. A shield was measured for shielding effectiveness in a reverberation chamber with various thermal interface materials inside.

Choice of Shield Material matters to Thermal Performance

The BLS material itself influences overall thermal performance because it plays a role in both the surface case temperature and the IC junction temperature. Tests indicate that the Al BLS provides better heat spreading than the stainless steel BLS because the AI BLS reduces the hot spot temperature on the top surface of the case. There is an advantage in using materials with higher thermal conductivity (Tc) as BLS increases with the size of the case and PCB. This might not be important for less sensitive applications. But it needs taken into consideration for applications where thermal performance is critical/span>

| Features |

|---|

|

| Value |

|

| Market |

|

GENERAL CATALOGUE

Euro Technologies offers a wide selection of products. Inside the general catalogue are described, each range, including its features and benefits, specifications, the available variants and possible applications.